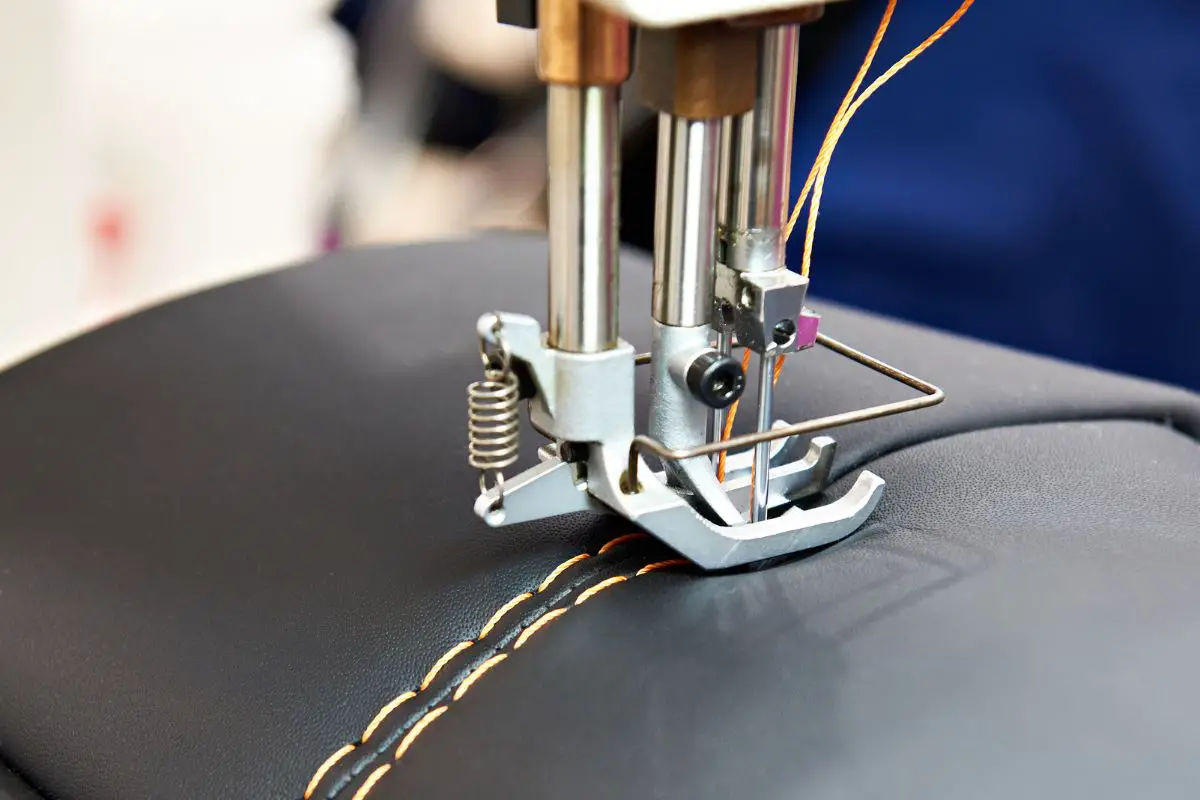

It’s so frustrating when your sewing machine jams, right?

You get together all the fabric, needles, and thread that you need to begin your new project, you’re full of excitement and then when you press your foot on the pedal, all you get is a whirring sound.

The machine might also get a few stitches done before the thread tangles up.

But don’t despair, as there may be a few easy-to-resolve reasons for why this is happening, and we have all the details below!

The Handwheel Is Stuck

Your handwheel should be able to move easily, so if this isn’t happening then something has gone wrong.

When your sewing machine is stuck, the handwheel is difficult to move and this can be because the fabric or needle is stuck, or because the thread is all tangled up.

If you have resolved these issues and the handwheel is still stuck, then it’s time to get your sewing machine seen by a professional to fix it.

The Needle Is Caught In The Fabric

It’s always frustrating when your sewing machine is consistently getting stuck during a project, especially when your needle gets stuck and won’t budge.

This isn’t just annoying, but also can cause your project to end in disaster.

There are a few reasons why your needle is getting constantly stuck in the fabric.

Thread And Needle Size

When you’re using a needle that isn’t the correct size for your fabric, you’re going to experience consistent jamming.

Therefore it’s important to ensure the thread and needle you’re using has the right thickness, and that you’re using a needle and thread that is suitable for the fabric you’re using.

The Thread Is Tangled

When a rope of thread tangles in your bobbin case then your needle will consistently jam.

To solve the problem, switch the sewing machine off and lift the presser foot and needle so you can remove the needle plate.

Clean the needle plate thoroughly and put it back, and this should hopefully resolve the issue.

Poor Quality Thread

The quality of your sewing thread is everything, and while buying cheap thread may seem like the more budget-friendly option, it may cause a lot of problems that will cost you more in the long run.

Thread that is poor quality will shed a lot of lint that can get stuck in your machine and cause jamming.

The thread might also tangle up in knots, which can also cause jamming when trying to force the fabric through. Thread that is poor quality is also more likely to break.

If you’ve checked the feed dogs, machine, needle, presser foot, and thread tension and have found no problems, then it may be that you just need to buy higher-quality thread.

We’re sure you’ll notice the difference when your sewing machine runs smoother and your projects look amazing.

The Length Of The Stitch

Yes, this could also be the cause of the problem! If the stitch length is too thin, then it may cause your sewing machine to jam.

The Needle Is Bent Or Broken

If there is an issue with the needle then this can also cause the sewing machine to jam. A broken or bent needle stops the thread from piercing the fabric.

Take a look at the needle and check it for any issues. If everything is looking okay but problems persist, then you could be using the wrong size or type of needle for the stitch pattern.

You should also check if you’re inserting the needle correctly.

The Presser Foot Is Locked In The Up/Down Position

If the presser is stuck in the down position, you won’t be able to place your fabric underneath, and this could be because of a broken lever.

If the lever of the presser foot breaks you will need to fix it, and it’s recommended that a professional do this.

Or, you can replace the entire presser foot. You should change your presser foot regularly to suit your needs.

However, it’s more frustrating when your presser foot locks in an upright position, and it’s physically impossible to sew. There are a few reasons why this problem occurs:

- Broken gears in the machine.

- The machine is stuck in bobbin mode.

- There is debris stuck close to the presser foot.

However, if you’ve gone through these problems and none of them are the case, you should take your sewing machine to a professional.

The Sewing Machine Is Locked In The Highest Speed

While it can be enjoyable to sew at full speed when you’ve reached certain areas, your machine going at full speed isn’t beneficial for complex areas, and so it’s important to regulate the pace of your sewing.

If your sewing machine is stuck at the maximum speed, you will need to take your sewing machine to a professional.

Let’s take a look at some of the possible explanations for why this happens:

Issues With The Motor

Issues with the speed of your sewing machine might be due to a problem with the motor.

A broken motor can influence the speed of your sewing machine, and if you can’t resolve this issue by yourself, it might be worth taking the machine to a professional.

The Foot Pedal Is Stuck

If your machine is stuck in maximum speed, it could be because of a problem with the foot pedal. The foot pedal regulates how fast your sewing machine goes, so this is the first place to check.

It may be that something is stuck in the foot pedal so it’s stuck at a certain speed, so you should look for debris and other dirt to make sure everything is in proper working order.

If the foot pedal is clean and you’re still experiencing problems, take a look at the power cord.

Sewing Machine Is Unable To Reverse

Your sewing machine’s reverse lever lets you sew backwards, and it is crucial for starting a stitch.

Before you begin sewing, it’s common to keep your stitch in place by sewing forwards and backwards for half an inch.

This is a standard technique that many sewers use to ensure their stitching doesn’t unravel. Once you’ve finished sewing you can still use the reverse function to keep your seam in place.

While sewing backwards is a crucial technique, nobody wants their sewing machine to only be able to reverse as it will be impossible to sew effectively.

You might be wondering why your sewing machine is stuck in reverse, so let’s take a look at some possible explanations.

Issues With The Feed Dog

The feed dog is responsible for the smooth backwards and forwards motions of the fabric. However, the feed dog can also get stuck in reverse and not allow your machine to sew forwards.

If this is the problem, changing the settings of your machine won’t be enough. You’ll need professional intervention.

Debris or lint in the feed dog area can clog the mechanisms which stops them from moving. Cleaning out the dirt and lint can loosen the jam.

You should make sure to lift your feed dog up so it can properly grasp the fabric.

Issues With The Settings

Some issues may not be with your sewing machine. Rather, it may just be that your machine has been left in reverse settings.

To make sure this isn’t the issue, turn the machine off and on, check the reverse lever is off, clean your bobbin and make sure it’s correctly installed.

If neither of these issues are responsible and you’re not sure what is, consult a professional.

Issues With Software

If you have a computerized sewing machine that continues to jam, there may be a problem with the software.

This is because the whole sewing machine is operated by a computer system. Technology isn’t always perfect, and computerized sewing machines are no exception.

The issue may be a software malfunction, or that your sewing machine needs to be upgraded.

If you have a good understanding of the software of your sewing machine you should be able to fix the problem yourself, but if you need some help, it’s worth contacting the manufacturer’s customer service.

If they are a reputable company, they should easily be able to help you.

Issues With The Reverse Lever

The reverse level is responsible for the reverse sewing functions of your machine so stitches can be tightly secured.

It’s often a button or a lever, and if this is where the problem lies it might be difficult for you to fix it on your own.

If you’re unfamiliar with the internal mechanism of your sewing machine, you’ll most likely need to consult a professional.

Bobbin Mode Is Jammed

One of your sewing machine’s jobs is to wind the bobbin, and if you try to do this yourself then your thread will have the wrong tension.

Still, there are a couple of reasons why your machine might be stuck in bobbin winding mode.

The Bobbin Software Has Malfunctioned

If you are using a digital sewing machine and it’s in need of an upgrade or troubleshooting, then it may get stuck in bobbin winding mode.

If you’re not confiding doing this yourself, contact the manufacturer’s customer service to see if they can help.

Machine Is Stuck In Bobbin Mode

Some sewing machines have a switch or lever that allows you to turn on its bobbin winding mode (see also “Sewing Machine Not Picking Up The Bobbin Thread“). If you can’t turn this off, then consult a professional who can do this for you.

Sewing Machine Is Locked In Zigzag Mode

Zigzag stitching is useful for areas where a straight stitch line isn’t available, like when you’re reinforcing buttonholes or sewing fabrics that are stretchy.

Using zigzag stitching on a couple of areas is one thing, but having your sewing machine permanently stuck in zigzag mode is another! But what should you do if you can’t turn off zigzag mode?

Consult your sewing machine manual to see if there are any useful solutions, and if you can’t find any, get in touch with the manufacturer’s customer service.

The Fabric Is Stuck In The Machine

Having your fabric get stuck in your machine can be very annoying, and a few factors can be at play.

When your fabric consistently gets stuck, it can seriously hinder your project, and when you’re using expensive fabric that is the last thing you want.

Let’s take a look at a few reasons why your fabric may get stuck in your sewing machine.

Using The Wrong Needle

Firstly, before you start any project you need to ensure your needle is sharp. But the needle doesn’t just need to be sharp, but correct and suitable for whatever fabric you’re sewing.

For example, to correctly sew a heftier fabric, you will need a larger needle.

The Bobbin Or Needle Plate Is Dirty

If your fabric is jamming whilst you sew, then you may simply need to give your machine a clean.

The needle plate and bobbin get dirty and dusty easily, so it’s important to clean it regularly so your fabric doesn’t get stuck.

Plus, shreds of fabric and broken threads can get stuck in the bobbin area.

Wrong Stitch Length

To avoid getting your fabric stuck in the machine, you should adjust your stitch according to the fabric you’re using.

The stitch length will depend on how much your fabric weighs, and it’s important to be mindful of this, particularly when you’re sewing stretchy, knit fabrics.

To make sure you’re using the right stitch, experiment with just a small amount of fabric before you can begin your project.

Thread Is Caught In The Bobbin

There may be a few reasons that the thread tangles in the bobbin.

Issue With The Bobbin Threading

If your bobbin is incorrectly threaded it can lead to jamming issues with your machine. Your bobbin thread will be unable to properly move if the bobbin isn’t correctly wound or if it’s knotted.

You can check your bobbin and if the thread is tangled, it’s pretty easy to fix yourself. If you’re unable to fix this however, re-thread another bobbin and see if that solves the problem.

Issue With The Tension

When the threading tensions on your sewing machine are wrong, your thread tangles in the bobbin.

This can happen from the top or bobbin thread, so you should check both threads to see if you can solve the problem.

Make sure that the top thread can feed through the sewing machine with nothing in its way. But if you’re still experiencing issues, you can just re-thread your machine.

If there is an issue with the bobbin thread, shift the screw on the bobbin case to adjust the bobbin case tension. When you use a thinner or thicker spread than is necessary, it can lead to tension issues.

The Upper Thread Has No Tension

In this case, the bobbin isn’t the issue, but is something people regularly believe when they see a lot of thread tangled under the fabric.

In fact, the issue is with the tension of the upper thread, when the sewing machine is lacking in upper tension to pull the thread up through the fabric.

When this happens, it’s a good idea to re-thread the needle per the manufacturer’s guidelines for your sewing machine with the presser foot raised.

Your Machine May Be Clogged

Sewing machines clog because of debris such as lint and dust getting stuck inside, and this is why it’s so important to set aside time to clean your machine and get rid of any dust or debris that clogs up during your sewing projects.

If jamming happens because of a clog in the machine, turn your machine off, un-thread it, and thoroughly clean your whole machine, paying particular attention to its working mechanisms.

You can blow away any dust, lint, or other debris, or use a small brush to remove it.

You should also make sure that you regularly lubricate the metal parts of your machine so you get a smooth performance every time.

When blowing any residue from the bobbin area, use canned air. To stop this from happening again in the future, set aside time every month to clean and lubricate your machine.

If you sew every day, you should clean and run maintenance on your sewing machine more frequently than that.

Final Thoughts

We hope our article has given you some insight into the most likely reasons your sewing machine keeps jamming, and what you can do when this happens so you can get back to sewing as soon as possible (see also “Reasons Why Your Upper Thread Keeps Breaking While Sewing“).

While there are numerous factors to consider, one of the best ways you can prevent your machine from jamming is to regularly clean and maintain it so it’s always in perfect working order.

Dirt and debris clog up important parts of your machine and are usually the culprits when your machine is continuously jamming.

Cleaning and maintaining your sewing machine doesn’t just apply to traditional sewing machines but computerized ones too.

While you may not have to keep a digital sewing machine well lubricated for the parts to run smoothly, you do still need to carry out regular system updates to ensure the software is running properly.

You should also make sure you are using the correct needle for your projects, as this can also cause issues like jamming.

If you’re ever unsure what the issue is, or don’t feel confident to tackle the problem yourself, seek the help of a professional or the manufacturer’s customer service.

- How To Sew Fabrics Together - June 5, 2023

- How Many Stitches Per Inch? - June 5, 2023

- How Long Does It Take To Sew A Dress? - June 5, 2023