Are you wondering why your upper thread keeps breaking while you’re trying to complete a project with your sewing machine?

This can be particularly frustrating when you’re halfway through a new project, and the thread keeps snapping.

If you’re wondering why this keeps happening to you, you may be wondering if your trusty machine has begun to deteriorate.

Well, before you start looking for a new machine to replace your old one, continue reading.

The issue may be easily fixable, and may not even have anything to do with the quality of your machine.

It may be as simple as replacing your thread, or taking a look at the inside of your sewing machine (see also “Common Reasons Your Sewing Machine Keeps Jamming“).

In this article, we will look into why your upper thread keeps breaking while sewing, and how you can fix this issue (see also “Why Does Thread Keep Bunching Underneath My Fabric?“).

Additionally, we will look into how you can avoid these issues from happening in the future.

So, let’s get into it.

9 Reasons Your Upper Thread Keeps Breaking

Below, we have listed 9 reasons why your upper thread keeps breaking.

Take a look through, and identify which of these reasons would make the most sense for you and your current situation.

Your Sewing Machine Is Poorly Threaded

Sometimes experienced sewers occasionally wrongly thread their machine.

If your sewing machine is malfunctioning or your upper thread tends to break, your sewing machine may not be threaded properly.

To start fixing this issue, you will need to make absolutely sure your thread take-up lever is situated at the highest position.

Next, carefully undo all the thread from the sewing machine, and then re-thread it from the start.

Following the directions in your user handbook, you should hook your thread spool and draw your thread into your tension discs and thread guides.

Once you’re done, allow a four-inch length of thread to hang loose after pulling the thread through into the needle’s eye.

You may find that, after doing this, your upper thread should no longer break during use.

Your Thread Tension Is Excessively Tight

For various fabric and thread types, your thread tension should indeed be altered, and you should ensure that the thread in your bobbin and top thread are the same weight.

If you choose not to, your thread might snap due to uneven stress.

Producers of sewing machines highly advise against tinkering with your bobbin thread tension excessively, but if your thread continues snapping while you sew, you must try modifying your upper thread tension.

The machine will yank your thread and damage it if your tension is too excessive. Simply ease it up by adjusting the tension dial in the opposite direction to repair this.

A sewing machine maintenance professional can restore your bobbin tension if you’re having trouble setting the correct tension.

The good news is that you can solve this yourself quickly and easily.

The Needle You’re Using Is Broken, Crooked, Or Blunt

Your sewing machine needle may become worn or crooked with time, particularly if you often stitch through dense material.

Your thread may be snapping regularly due to inherent defects or burs that occur during the production of sewing machine needles.

Sometimes you will find a needle that is broken or bent before you even put it into your machine. Although this isn’t a common occurrence, it is one that happens occasionally.

Your automated thread hook won’t align effectively if your needle is broken. You must change your needle right away if this is the case.

Producers of sewing machines advise changing your needle after each project, however the majority of people don’t do this.

Even if you don’t replace your needle all that frequently, you should still do so occasionally, particularly if you notice that it is getting dull.

To ensure you always have a spare sewing machine needle available in the event of a bent needle, we advise purchasing a bulk container of sewing machine needles.

You’re Not Employing The Proper Needle

Producers of sewing machines advocate changing your needle before each project, as we covered in the previous section.

In this manner, your needle will be razor-sharp from the start and will have no trouble piercing your material.

If the needle cannot effortlessly penetrate your cloth, it may cause your thread to clog and snap if you are not using a sharp, clean needle.

When you’re stitching through heavy material, like tweed or denim, this is even more likely to take place.

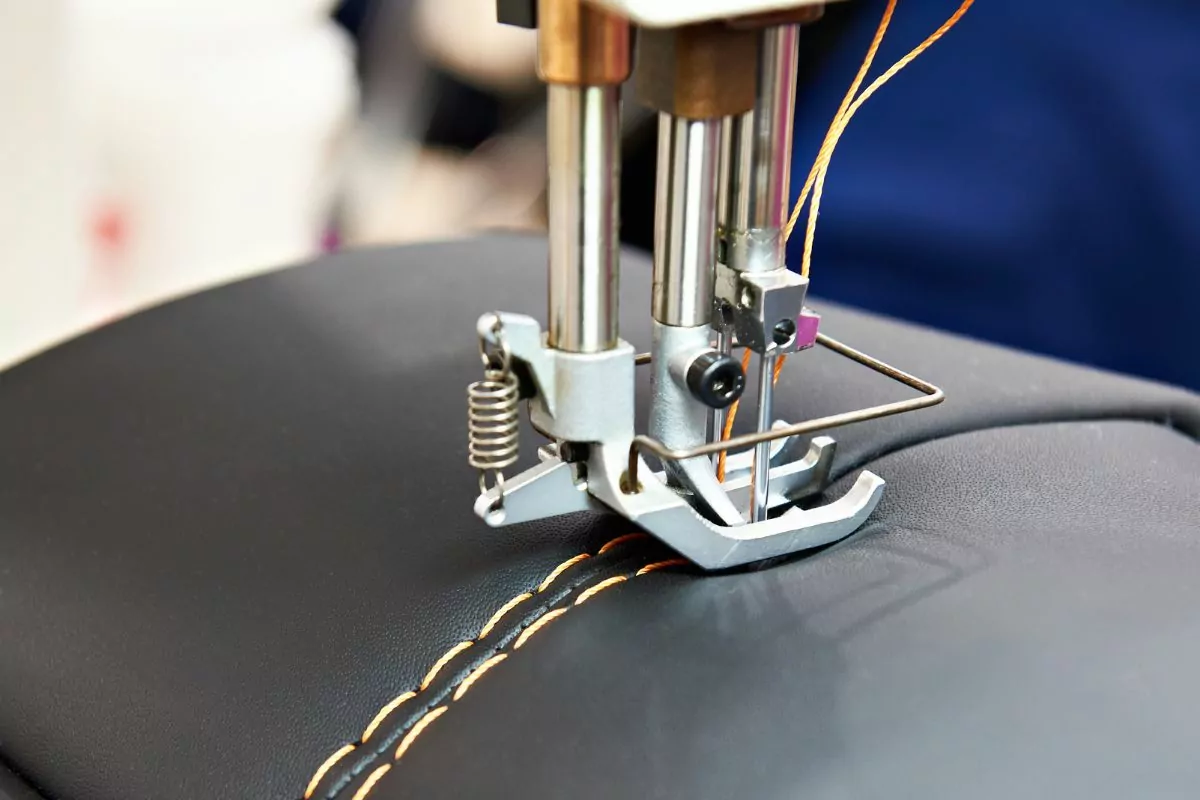

A standard sewing needle will eventually break while straining to sew through leather, since it is so thick.

Therefore, you will want to check that the needles that you are using are suitable for your specific project.

If the needle is not strong enough to penetrate the material, it will easily break, and so will the thread as you use it.

Your Needle Is Not Properly Positioned

As you sew, a tiny screw secures your needle in position on the inside of the machine.

With time, this screw may become loosened, which will eventually result in your needle to slip out of the machine.

When you’re using the machine, you might also knock the screw, which would cause it to undone.

This is problematic because your needle could break if it hits your bobbin case and is not fully kept in.

Prior to actually starting any project, you must make very sure your needle is fully entered and is as secure as it can be.

On your sewing machine, you must also take care to avoid inserting the needle backwards.

When you attach the needle, the underside of the upper shank, which is curved and has one flat side, will need to face the backside of your sewing machine.

The thread will be affected when you operate the machine if you put your needle incorrectly, as the needle may break upon impact with your bobbin case or throat plate.

You Have A Damaged Take-Up Lever Spring

A damaged or bent take-up spring, which is attached to the tension dial of an embroidery or sewing machine, is another factor that can cause your thread to break while you’re stitching.

When the pick up lever tugs the thread through into the machine’s tension discs, the spring acts as a kind of suspension system, absorbing some of the force and stopping the thread from breaking.

Therefore, if the spring has been damaged, the thread is more likely to snap.

Your spring is likely damaged if your thread rips as soon as you start sewing or if you can’t see the take-up lever moving upward and downward.

To get the spring changed, send it to a sewing machine repairman to get it fully fixed.

Your Thread Is Of Poor Quality

A reason that your thread could be breaking when you sew because of the low-quality thread you’re using.

Fortunately, this is a simple problem to solve—all you have to do is switch to a stronger, more resilient, higher-quality thread.

There are various weights of thread to choose from.

Some threads are so thin that even a slight tug may cause them to break, while other threads are so thick that they will tear in the needle’s eye, or in the tension discs.

You should use caution whenever you select thread for craft projects. Since large quantities of thread typically contain low-quality items, refrain from buying them.

This thread works well for little tasks and hand stitching, but it may not be sturdy enough to be used for machine sewing.

You’re Stitching Too Quickly

Your sewing machine needs adequate time to do its duty in order to puncture the material and make the locking stitch.

You can create unequal tension and damage your thread if you stitch too quickly or inconsistently.

This is a simple technique to break the thread if you are stitching too quickly.

In order to avoid this problem, you should sew more slowly, particularly if you are sewing into thicker cloth or numerous pieces of material.

The next time you attempt a sewing project, proceed with caution and pay attention to your sewing speed.

Remind yourself to slow down if you are moving too quickly in order to protect your sewing machine and thread.

Your Bobbin Case Is Loaded With Debris

As you sew, bits of fluff will accumulate in the bobbin case as thread debris snags and collects there after several consecutive uses.

Your sewing machine may suffer major harm once the bobbin case is completely blocked with lint.

Lint buildup in the bobbin case can affect hook timing, which can lead to thread snagging and breaking.

You should try to clean your sewing machine periodically to make sure it operates correctly, in order to completely prevent this problem.

Always remember to examine your bobbin case to make sure it hasn’t totally blocked up or started to fill up after every sewing project.

Final Thoughts

Thankfully, this is not an issue that means that you will have to spend extra money on a brand-new sewing machine.

It could simply be the case that you are using the wrong kind of thread for your chosen material, or that you need to replace your current needle.

We hope that you identified the issue while reading through our list above.

If you’re still struggling to find out what is wrong with your machine, we recommend contacting a professional to take a look for you.

We hope you found this article helpful.

- How To Sew Fabrics Together - June 5, 2023

- How Many Stitches Per Inch? - June 5, 2023

- How Long Does It Take To Sew A Dress? - June 5, 2023